Introduction

Due to the flexibility and plasticity of LED display screens, LED manufacturers have given a lot of inspiration, and thus have created a lot of LED displays products with different types.

This article selects 7 classification methods of LED display screens from the well-known classification methods. This can best help everyone understand the LED displays currently on the market.

Rental and Fixed LED Display

Rental LED displays and fixed LED displays are two commonly used types of LED displays that are often heard when you first come into contact with LED displays.

Rental LED display

Rental LED display screens are represented by rental cabinets that are easy to disassemble and are specially used for stage performances, artistic evening parties and other events. It is suitable for storage after the performance is completed and moved to the next event location for continued use.

Fixed LED Display

The fixed LED display screen is an LED display screen that is opposite to the rental LED display screen. The biggest difference from renting an LED display is that it cannot be moved and is suitable for long-term use in the same place.

SMD LED display and COB LED display

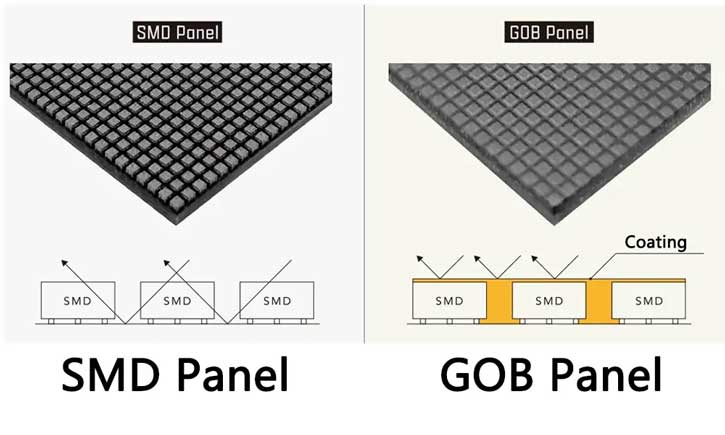

This is an LED display produced by two different technologies. The biggest difference between them is that the LED display screen produced by SMD technology has a minimum point pitch equal to 1mm. If it’s under this size, it can only be manufactured using COB technology. Let’s take a look at a more detailed comparison between the two.

Packaging technology

SMD LED display is an LED display made using surface mount technology. A sealed container is equipped with three LED lamp beads, red, green, and blue, that emit different colors.

Through the three-color mixing theory, we know that when red, green, and blue are mixed, 16,777,216 colors can be produced. These colors are enough to imitate all the colors in our real world, so any wonderful picture can be created.

Different from the traditional SMD surface-mount packaging, the LED display screen produced by COB technology directly integrates the light-emitting chip into the PCB board, so it can achieve smaller and finer pitches.

Raw material cost

SMD and COB use two different machines. Since the COB LED display is too fine and must be operated by a high-precision machine, the price of the machine that makes COB is much higher than that of the machine that makes SMD, but the benefits The error rate of LED displays encapsulated by COB technology is much lower than that of LED displays encapsulated by SMD technology. From a long-term perspective, the price of COB LED displays is lower than that of SMD LED displays.

Another point is that COB eliminates the concept of brackets, has no electroplating, no reflow soldering, and no patches, and the production cycle is reduced by 30%. In other words, if the production cycle of the SMD takes 10 days each, then the COB machine only takes 7 days to complete production.

Optical and electrical properties

This is an advantage and feature that SMD cannot surpass. The full-color COB display has good color consistency and a large viewing angle, so the picture is very high-definition and realistic.

In terms of brightness, spot uniformity and color mixing, it even beats SMD. This is mainly because there are hundreds of light-emitting points on the COB dispensing plate. These luminous points are all concentrated on a reference point. It is for this reason that the light spot is more uniform.

SMD, on the other hand, needs to stick the light-emitting points on the PCB board one by one. When sticking, the light spots are unevenly displayed, causing the final visual effect to be completely incomparable with COB.

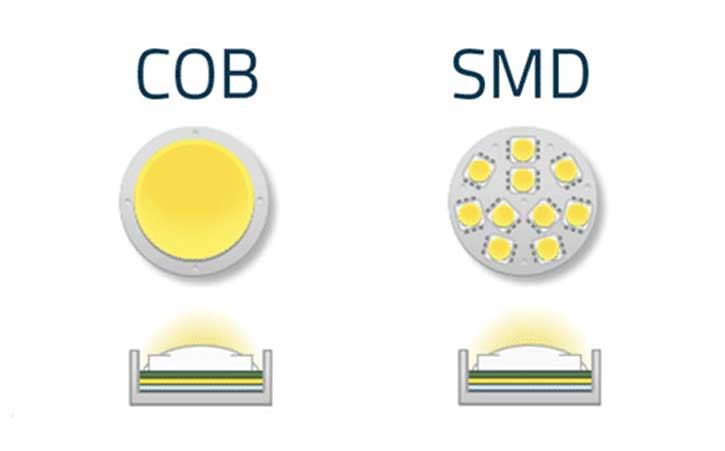

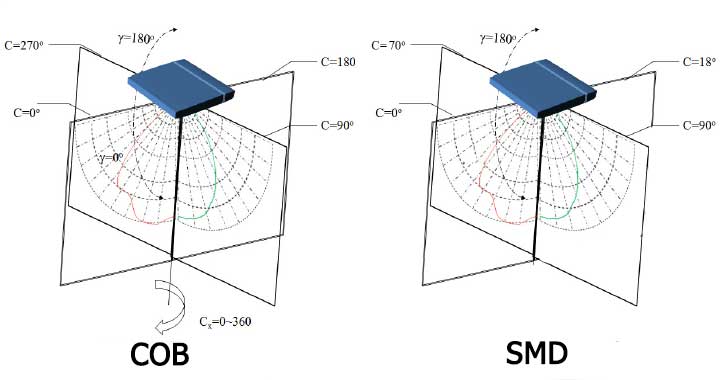

The following is a comparison picture of the appearance and angles of light shape of dispensing and SMD.

Lumen maintenance

The lumen maintenance rate of SMD can only reach 91.8%-92.5%, but COB uses heat sink process technology to ensure that the lumen maintenance rate of the produced LED display can reach 95%.

COB packaging substrate

The traditional packaging form of SMD is to mount multiple discrete devices on a PCB board to form an LED display. COB is an integrated package and a surface light source. It not only has a large viewing angle, but also reduces the loss of light refraction.

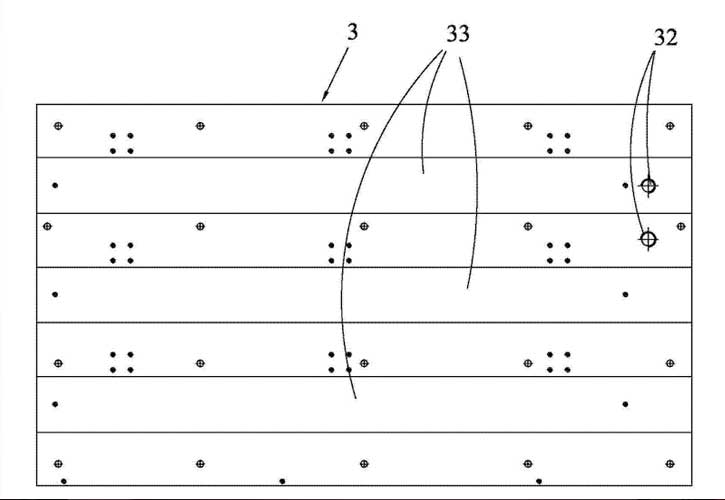

COB has a wider perspective. From the following light pattern diagram, we can see that the viewing angle of COB full color is much larger than that of SMD full color. The viewing angle of SMD full color is about 110 degrees.

However, the viewing angle of COB full color can reach 140–170 degrees without weakening the brightness. And the vertical angle also has a wide viewing angle of 140–170 degrees. These features are particularly advantageous in some applications. Here is a comparison of the light shape diagrams of the two:

From the above comparison, the visual effect of COB full color is better than that of SMD full color in terms of viewing angle and luminescence effect diagram.

Solid crystal placement

The RGB chips are placed in a straight line. There is a smooth curved lens above the chip. When the three-color light passes through the lens, it will be refracted, so that the three-color light is mixed more evenly. This uniform light spot gives a very good visual effect.

However, SMD full color does not have this feature, so the top of SMD is a flat surface, so the refraction effect occurs. The following is a comparison of the light effects of the two, which can more clearly see the advantages of COB full color:

From the light distribution curve chart, we can know that the COB full-color curves have good consistency among the three curves, while in the SMD full-color curve, the red light curve and the blue/green light curve are greatly separated.

Waterproof, moisture-proof and UV-proof

Problems with waterproofing and moisture-proofing are the main culprits that directly lead to quality problems such as failure, dimming, and rapid attenuation of outdoor LED displays during use.

COB uses a packaging method of dispensing glue on the board to form a lens. Therefore, when used outdoors, its waterproof, moisture-proof and UV-proof performance has reached an admirable level.

On the other hand, most SMDs use PPA material brackets. Although the PCB board is coated with three-dimensional It is paint-proof, but there is still a gap with COB in terms of waterproofing, moisture-proofing and UV protection.

Many people may be curious, since COB almost completely beats SMD in terms of advantages and performance, why are the LED displays on the market still dominated by SMD instead of COB?

The main reason is price. We mentioned above that although COB may be more cost-effective than SMD in the long run, the problem is that the most important thing about the factory is the operation of cash flow.

We all know that the more sophisticated the equipment, the more difficult it is to be completed in a factory. This results in factories and factories being connected in series with each other relying on cash flow. It is impossible for a factory to reduce the price of LED display screens with long-term holding as a future plan.

If you want to use the COB manufacturing equipment purchased at a high price, you must spread these costs equally to each LED display screen produced, so COB It is very common for LED displays to be 3–5 times more expensive than SMD LED displays.

Therefore, you can choose the right LED display according to your budget needs.

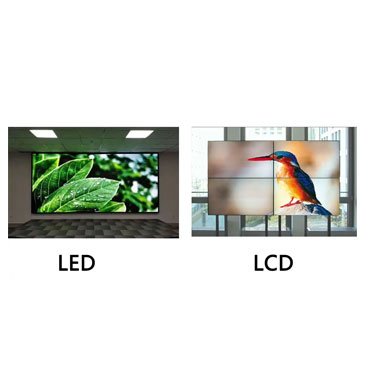

Indoor and Outdoor LED Display

Indoor LED displays and outdoor LED displays are two types of LED displays that are generally referred to. This means that all LED displays used indoors, such as small-pitch LED displays, conference room LED displays, etc., can be classified as indoor LED displays. Similarly, LED totems and light pole LED displays used outdoors can be classified as outdoor LED displays. Let’s take a look at the differences between the two.

Brightness

Indoor LED display is low brightness, usually between 800-2000cd, Outdoor LED display screen is high brightness, usually between 2000-6000cd;

Pixel Pitch

Since the viewing distance of indoor LED displays is relatively close, in order to achieve better display effects, the pixel pitch of indoor LED displays will be controlled between 1-5mm. The viewing distance of outdoor LED displays is relatively far, so the pixel pitch of outdoor LED displays is between 5-10mm.

Price

If they are of the same model, the price of outdoor LED displays is usually higher than indoor LED displays. Taking P4 LED display as an example, outdoor P4 LED display is generally 50% higher than indoor P4 LED display.

The reason why this happens is that outdoor LED displays need to meet two basic conditions: waterproof and high brightness, while indoor LED displays do not meet these two conditions at all. It is for this reason that the same model, outdoor LED displays, will always be more expensive than indoor LED displays.

Climate

The outdoor climate is always very severe, it may be freezing weather, or it may be high temperature weather. In order to make the outdoor LED display screen operate normally, it is necessary to use a dedicated power supply and wires, which is also significantly different from the indoor LED display screen.

Single, Double Color LED Display and Full-color LED Display

Single Color LED Display

As the name suggests, it is an LED display that can only emit one color. The commonly used ones are red, green, and white. This kind of LED display is mostly used in the middle of the store to display time or store discount information.

Double-Color LED Display

Double-color is an LED display that packages two different colors of lamp beads together. Double-color LED displays are mostly used for traffic signs. Although the double-color LED display looks like it just adds one more lamp bead than the single-color one, the types of colors it displays may surprise you. It can display 65,536 colors.

Double-color LED displays were commonly used 10 years ago, and their prices are not much different from full-color LED displays. Now they have been replaced by full-color LED displays.

Full-color LED Display

The LED display screen is composed of three colors of LED lamp beads: red, green, and blue. The earliest form is the direct plug type. This type is operated manually, has large errors and is prone to errors. Now it has been changed to the packaging method of the SMD.

Synchronized and Unsynchronized LED Display

This type of LED display is just like a computer monitor. It only has a display function. LED displays with synchronous and asynchronous functions mainly refer to LED displays with synchronous control cards and asynchronous control cards installed.

The LED display screen of the synchronous control card works in the same way as a computer monitor. It maps the image on the computer monitor point-to-point in real time at an update rate of no less than 60 frames/second, and can display time, video and other information in real time.

There are many ways to control content display, and you can choose network cable, Wi-Fi, 4G, etc.

The display screen of the asynchronous control card is also called the offline control system display screen. Mainly when offline, various texts, images and animations can also be displayed.

Different from the LED display screen of the synchronous control card, the LED display screen of the asynchronous control card can only be edited by the computer, and then placed into the frame memory through the RS232/485 serial port, and then displayed and played screen by screen.

The shape can be divided into:

Generally, a square or rectangular LED display is called a conventional screen. In addition, there are also special-shaped screens assembled using flexible LED modules. This special-shaped screen can be made into round, rectangular, arc, canned Shape, curved surface, spherical, etc., and can be spliced into various shapes as needed.

The application industry use environment can be divided into:

- Advertising screen

- door sign screen

- information release screen

- queuing screen

- service window screen

- traffic guidance screen

- taxi top screen

- vehicle screen

- stage background screen

- roof screen

- logo screen

- backpack screen

- badge screen

- Workshop kanban screen

- environmental monitoring screen

- monogram screen

- command center monitoring screen

- window transparent screen, etc.

Conclusion

We have listed the common classification methods of LED displays on the market and introduced in detail the differences between the two. We hope it will be helpful to you.