JYLED Technical Support Services

- handle various complex and changeable debugging problems.

- If you encounter LED control software debugging problems, please contact usin time and we will provide free technical support.

- Provide the latest LED control software for free download

- Provide free download of the latest LED control software product manuals

- 24 hours free technical support

LED Screen Software Free Download

Applicable To Windows Platform Installation

LED Control Software Brand (5)

With the widespread application of LED display screens, various components of LED display screens have gradually become familiar to people, including LED sending cards, LED receiving cards, and so on. How do these control cards responsible for transmitting and sending information achieve the transmission and delivery of information? Next, I will analyze its working principle and implementation method step by step, from shallow to deep.

What is an LED display control system?

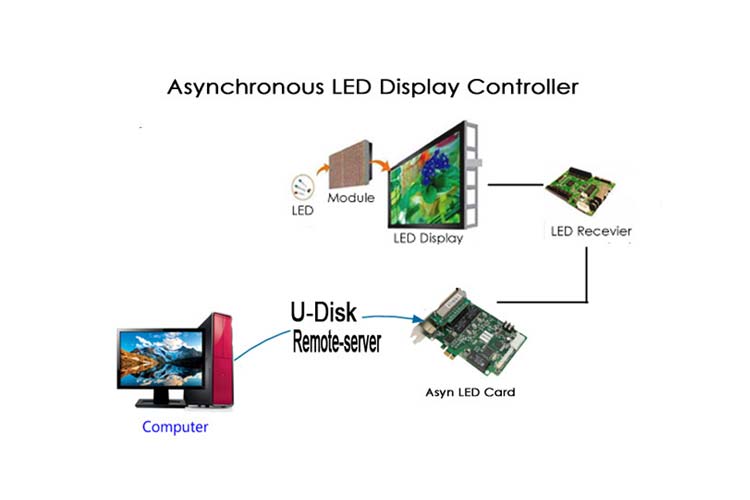

The LED display control system, also known as the LED display controller or LED display control card, is the core component that enables LED display screens to display various media information such as different texts, images, videos, etc., similar to a computer’s graphics card.

Principle of LED display control system

The LED display system is responsible for receiving media information from the computer’s serial port or DVI interface, storing this information in a frame memory, generating specific serial display data and scanning control timing according to the partition drive method, and recognizing and decoding it through the LED display screen.

The steps of recognition and decoding consist of three parts:

- Analyzing the components of the LED screen through the analysis of the dot matrix module and control circuit.

- Analyzing the composition structure of the LED display screen through the analysis of the single-chip microcomputer.

- Determining the scanning drive mode of the LED screen through the intelligent control module.

Through these three steps, the display of the LED display screen is ultimately achieved.

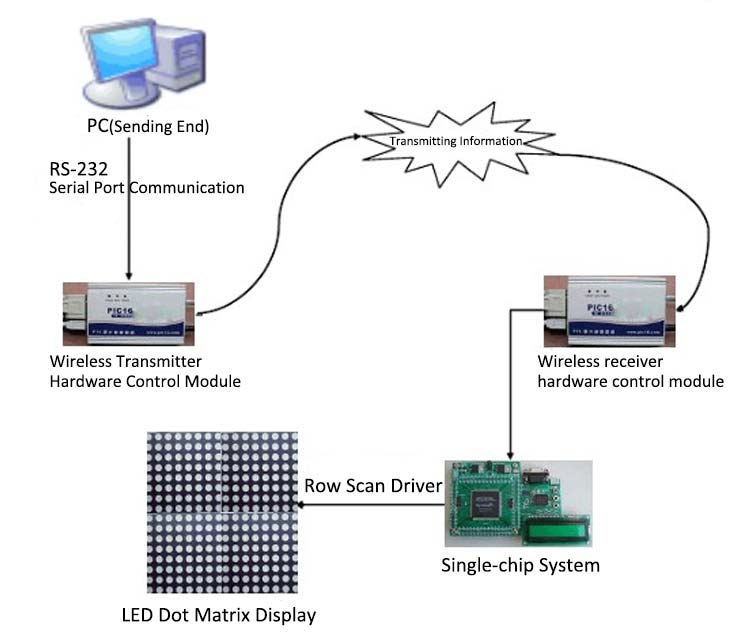

Based on the application of the LED display control system, the architecture and workflow of the LED graphic display screen are designed. Serial communication is used between the software system and the main wireless transmission control hardware system to complete program downloading, used for text information transmission.

Overall analysis of LED display control system

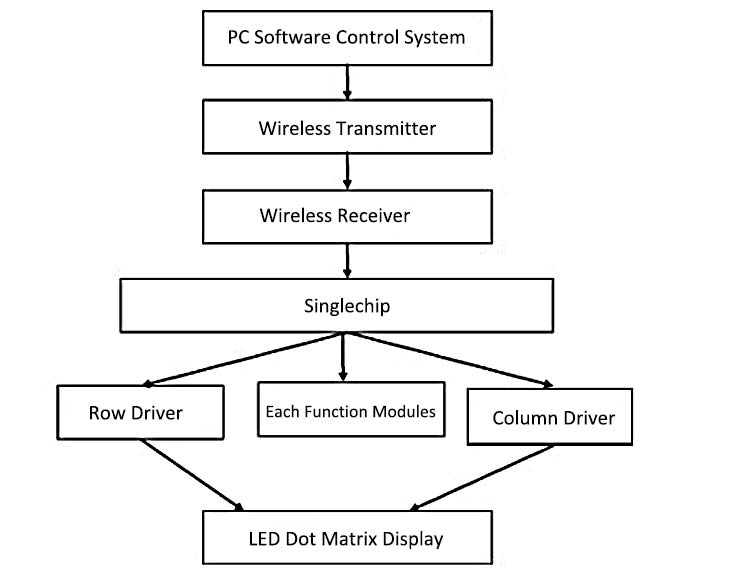

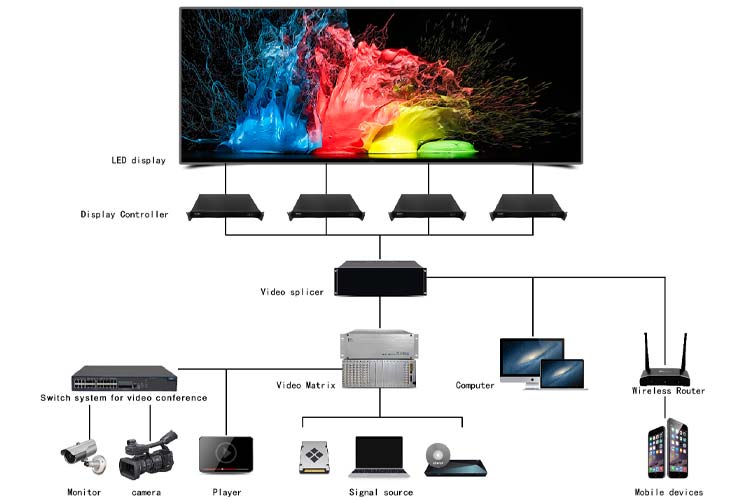

The LED display system consists of five core parts: software control system, wireless transmission system, device main controller, LED display matrix, and power supply system.

The basic structure is as follows:

System operation process:

- The software control system mainly encodes the information that needs to be displayed correctly and then inputs the edited information into the LED display screen.

- The wireless transmission system is mainly used for convenience when there is no computer available or when the computer cannot connect to the network. The wireless transmission system supports transmission methods such as WiFi, 4G (compatible with 2G and 3G).

- The LED display matrix controls the display of information by controlling the current and then arranges it under the scanning drive mode of the single-chip microcomputer, thereby realizing the graphic display function of the LED display screen.

- The power supply system provides power for the operation and operation of all systems.

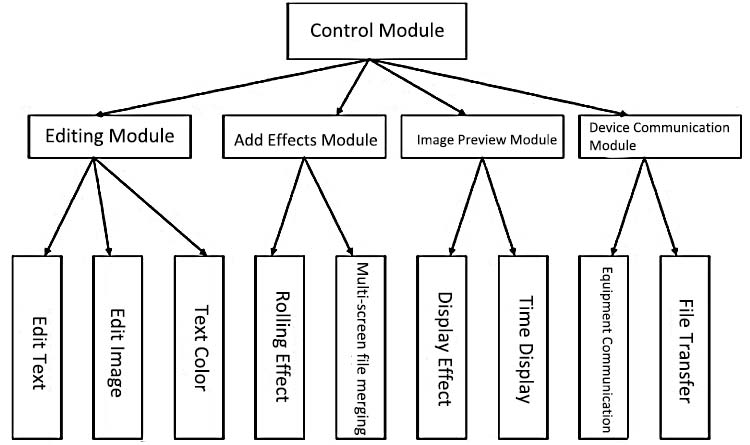

Analysis and design of LED control software modules

The LED control software module is divided into two main parts: editing part and control communication part.

The editing part mainly edits the input graphics and text, while the communication part completes the transmission of files to the single-chip microcomputer storage module through RS-232C serial communication.

Almost all LED control software is developed based on Windows, so preparing a computer with a Windows system is required for editing or debugging LED display screens. Here we introduce some basic functions that most software has.

In the Windows system, open the LED software interface, and then click on the text editing window, there will be an interface that is the same as the pixel points of the LED display screen. Then, there will be a toolbar similar to a Word document at the top of the LED software, which includes editing modules, drawing modules, color control modules, text editing modules, adding effect modules, etc. Let’s understand their usage one by one.

Editing module:

In addition to the cut, copy, and paste functions provided by Windows, the LED control software system also includes undo and redo functions. Clicking the undo function can undo the previous erroneous operation during editing. Clicking the redo function can repeat the most recent editing operation.

Drawing module:

Similar to drawing software on a computer, it mainly includes simple graphics drawing functions such as lines, rectangles, ellipses, circles, etc.

Color control module:

This corresponds to the three colors of red, green, and yellow of the LED display screen beads, achieving control over colors.

Text editing module:

This module is basically similar to a Word document, including font, font style, font size, boldness, effects, color text editing, and can also add text editing at specified positions according to different purposes.

How to edit LED display text?

First, select the text that needs to be edited, select the font selection box that pops up, and then select the text in various fonts for editing. If you need to edit at a specified position, you can call up the specific text position editing dialog box, and then enter the text and the abscissa and ordinate of the requested display position.

Adding effect module:

Often, we don’t just display static images, but need some dynamic effects, such as left-right scrolling output or up-down scrolling output. At this time, the adding effect module can be used.

- Original effect: Static display of information on the screen.

- Scrolling effect: It can realize information scrolling display from left to right or from top to bottom, and can also intersperse with static information for display.

- Single-screen information transmission: Save the edited and waiting-to-be-transmitted files.

- Multi-screen information transmission: Combine the edited and saved single-screen information into one file for transmission, thereby reducing the time for transmitting files.

Image preview module

Before file transmission, any form of font information saved can be previewed, and then integrated into the toolbar file open function button.

- Display effect: Through the preview before file transmission, we can adjust the arrangement order of static and scrolling display effects.

- Display time: Display the time interval between different screen display information.

The structure diagram of the software module is as follows:

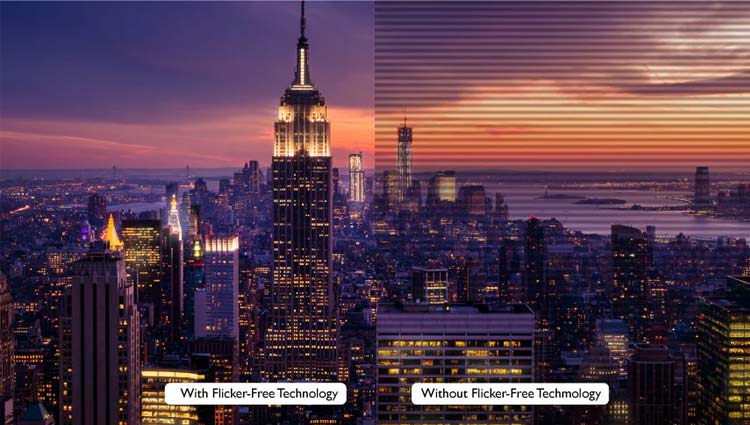

The control technology of LED display screens further improves

From the 1990s to the present, the control technology of LED display screens has been gradually improved. With the development and use of the fifth-generation “array” control system, the technical advantages of LED display screen control have been greatly improved, further improving the display signal processing technology.

What are the advantages of the “array” control system?

– The original frame rate has been increased from 60Hz to over 120Hz, solving the problems of flicker and water ripple, and improving the performance of LED display screens.

– The grayscale levels of the three primary colors of red, green, and blue have been increased from 256 levels to 1024 levels, making the images on LED display screens more vivid, with better color reproduction and more realistic images.

– Finally, LDVS signal transmission is used to maximize the avoidance of signal loss, improve the consistency of the entire display screen, and avoid the occurrence of color difference in the display.

How to match a suitable control system for LED display screens?

There are various brands of control systems used in LED display screens on the market, with a plethora of subdivisions emerging from different brands, presenting a dazzling array of choices. The types of control systems are further divided into many categories and application scenarios.

The types of control systems include receiving cards, sending cards, video processors, sending boxes, multimedia servers, and accessory systems for sensors used in conjunction.

The application scenarios of control systems include mobile, fixed installation, and rental scenarios. Fixed installation LED display screens involve placing the LED display screen and control system in the same or different positions within the same area. On the other hand, LED control systems used for rental purposes typically change locations with the movement of venues.

Therefore, when selecting a control system for LED display screens, it is necessary to consider and evaluate the stability, repeatability, and mobility of the control system. Mobility requires our control system to be solid, durable, impact-resistant, and stable in operation, with a focus on the video processor and sending card areas.

Currently, video processors on the market have integrated sending card functions into the processor, making them a combined device, which is what we commonly see as video processors nowadays.

Before selecting and matching the appropriate LED control system, it’s crucial to have a clear understanding of one basic point: sending devices of what brand must be paired with receiving card devices of the same brand, requiring the sending and receiving devices to be of the same brand.

What are the brands of LED control systems?

ommon control system brands include: Nova, Colorlight, Linsn, Huidu, Colorlight, Kystar,Mooncell, etc. These brands have high market share and brand influence.

What are the advantages and disadvantages of different brands of LED control systems?

Different brands of control systems each have their own areas of emphasis and specialties.

A. Novastar

Strong technical capabilities, excellent product performance, a wide range of product types covering all the products needed for LED display screens. Its receiving cards, sending cards, video processors, multimedia servers, asynchronous playback boxes, and other mainstream product models are favored and preferred by customers both at home and abroad, providing excellent customer experience. Many high-definition LED display screens for fixed installation and LED display screens for rental use use this brand. It is also a brand that many manufacturers currently cooperate with and use.

It currently ranks first in the global market share. Some frequently used models of receiving cards are: DH7508, DH7512, DH7516, MRV208, MRV412, MRV416, A5S, A5S Plus, A8S, A10S, etc. Some frequently used models of video processors are: VX400S, VX600, VX1000, VX16S, H2, H5, etc. Different models carry different total numbers of pixels.

Some frequently used models of synchronous and asynchronous playback boxes are: TB1, TB2, TB40, TB50, TB60, TU15, TU20, etc. Some models of control devices also support the following functions: they can display computer screens synchronously and play videos and images stored in the playback box asynchronously.

Therefore, they are named synchronous and asynchronous playback control boxes.

Advantages: Excellent product stability, simple debugging, fewer after-sales issues, high reusability, convenient matching and selection.

Disadvantages: Slightly higher prices compared to other brands and products of the same model, low cost performance. There are basically no control cards for monochrome and dual-color LED display screens. The main control card products are still concentrated in the application field of RGB full-color LED display screens.

B. Colorlight

A wide range of product types, comprehensive, can be seen in all types of LED display screens on the market, including conventional fixed installation LED displays, irregular LED display screens, and customized LED display screens. Its technical service team is large, and its after-sales service and handling of abnormal problems are timely, receiving consistent praise from customers.

Currently, it ranks among the top in brand influence in the domestic LED display screen control system market in China. Some frequently used models of receiving cards are 5A-75B, 5A-75E, E120, E80, E320, i5, i8, i9, etc. The 5A and E series receiving card products are mainly used in fixed installation LED display screens and rental display screens.

The I-series control cards are mainly used in small-pitch LED display screens and high-definition LED display screens. They are assembled with some aluminum chassis and need to be used with HUB adapter boards. The most common scenarios include conference rooms, exhibition halls, command centers, and art galleries.

Some frequently used models of video processors are X2S, X2M, X4S, X4M, X6, X8E, X16E, X12, X20, etc. Moreover, all of the above devices support switching between Chinese and English languages, meeting the usage needs in different countries. Different models have different numbers of network ports and carry different total pixel counts, so it is necessary to calculate and select the corresponding control device model based on the total pixel count of the LED display screen.

Some frequently used models of synchronous and asynchronous playback boxes are A100, A200, A35, A2K, A4K, etc. Advantages: Wide range of product types, excellent alternative solutions, rapid technical service response, medium product prices.

C. Linsn

One of the earliest manufacturers engaged in LED control systems on the market, its control systems and related products are distributed worldwide and are applied to LED display screens in many well-known places around the world. Many installation and technical service personnel at home and abroad choose to use this brand.

The main reason is that it was frequently encountered in the early working time, and many technical personnel are familiar with the debugging, maintenance, and after-sales service of receiving cards and video processors of this brand, and are more proficient in debugging software than other brands. Some frequently used models of receiving cards are RV908M3, RV998, RV216B, RV320A, etc.

The most commonly used sending card is TS802D, TS852, TS08, TS12, TS16, etc. Some frequently used models of video processors are X100, X200, X2000, X8208, X8212, X8216, X8406, X8408, X8414, etc., mainstream two-in-one video processor products.

D. Huidu

One of the most popular control system brands in the global market in recent years, its brand influence, attention, popularity, and market share have been steadily increasing. The asynchronous control systems produced by this brand company are deeply loved by a wide range of users and technical service clients because of their excellent software debugging interface, ease of use, and software support for 18 different languages, meeting the usage needs of customers from different countries. Moreover, many types of asynchronous control cards, including those used for monochrome LED display screens, full-color LED display screens, and outdoor LED displays, have a leading market share.

Some mainstream products frequently used for full-color receiving cards include HD-R712, HD-R716, HD-R708, among others. Mainstream sending cards include HD-C16L, HD-C16C, HD-C36C, HD-A3L, HD-A4L, HD-A5L, HD-A6L, and HD-A7 HD-A8. There are also very popular monochrome control cards on the market, including various types of control card products that support WIFI control, Ethernet control, and USB control for updating and broadcasting programs.

The advantage of Huidu solutions lies in the very cost-effective control cards launched in the field of monochrome and full-color asynchronous control methods, with a significant price advantage. Because most of these LED display screens have the characteristic of large length resolution and small width resolution, it is necessary for the control card to have ultra-wide bandwidth capability.

E. Kystar

The most cost-effective control system brand. All features are moderate. Some mainstream products frequently used for full-color receiving cards include G612, G608, G616, G628, R12, among others, with G612 being the star product and the most widely used product under this brand, with the highest market share.

Main sending cards include S2 and S4, among which S2 has the highest practicality. Because S2 is only a sending card and does not have the function of a video processor, currently, S2 needs to be used together with a video processor separately.

Mainstream video processors include KS600, KS880, KS960, KSV2, KSV2U, KSV4, KSV4U, among others, which are conventional and versatile products. Moreover, these models of products also have English versions of menu display interfaces, and the debugging and setting interfaces are relatively simple and practical.

F. Mooncell

A brand of control system solutions with potential and deep research and development capabilities. Mooncells control system solutions are mainly applied to differentiated, customized, and personalized LED products, not ordinary conventional LED display screens, but the key advantage of this brand lies in customized debugging. Technical personnel will know that many special-shaped LED display screens, such as LED spheres, LED round cakes, LED cubes, DJ booth LED display screens, immersive LED display screens, have special shapes and different characteristics in the debugging process, such as data offset, resolution cheapening, and point offset.

The scanning methods of LED display modules on the entire LED display screen will also vary, requiring corresponding debugging and linking of the entire screen parameters. Only the software developed by Moocell can easily, stably, conveniently calculate, clearly visualize the state, and accurately handle such debugging scenes.

The control cards commonly used by this brand include T75E, A75E, A716, A712, A708, A320, T6, among others, among which T75E, A75E, A712, and T6 are the mainstream products and the most popular products in the application market. The video processors mainly include MVB2S, MVB4S, MVB6S, MVB8S, among others. The asynchronous playback boxes mainly include MB1, MB2, MB4, MB6, among others.

What are the common problems in the use of control systems? How to solve these abnormal points?

Problem 1: Partial screen flicker of LED display.

The main manifestation is that a certain area of the LED screen displays abnormally, flickers, or has bright lines, which may cause incomplete display of the picture. The appearance of such problems is mainly due to abnormalities or damage to the control card on a single cabinet, which can be solved by first checking whether the power supply line of the receiving card is normal, whether the DC 5V power supply cable is well connected, and whether the network cable connected in series between cabinets is loose or damaged, and can be tried to solve by plugging and tightening the box.

If these procedures have been tried and still not resolved, it can be confirmed that the control card is faulty, and only need to replace the corresponding model of the control card, and then resend the parameters of the LED display screen with the computer, as with other control cards.

Problem 2: Entire screen flicker of LED display.

The main problems are due to the poor connection of the main network cable connecting the LED display screen and the video processor, which can be checked by checking the RJ45 interface and replacing a new main network cable.

The second reason can be checked by the HDMI cable between the computer and the video processor to confirm whether it is due to poor HDMI contact or the quality of the HDMI cable. The solution to these abnormal problems is to restart the plug and replace the HDMI high-definition cable.

Problem 3: Abnormal display of single LED display module.

The manifestation includes screen flowers and bright lines on the LED module, which is mainly caused by damage to a single LED module. The main reasons include short circuits caused by poor quality of the lamp beads, damage to the driving IC, and poor signal lines from the receiving card to the LED display module.

The solution to the problem is very simple, and can be solved by excluding and solving from these aspects.

- a. Replace the new LED display module

- b. Replace the long signal line from the control card to the LED display module or check and confirm whether the signal line is loose

- c. Confirm whether the power supply socket for the LED module is loose.

Problem 4: Black screen of single cabinet

This common problem is caused by the failure of the power supply inside the single cabinet or the malfunction of the receiving card, and can be solved by replacing a new power supply and receiving card.

How should different scenes correctly match and use suitable control systems?

a. Choose from the control mode For some conventional fixed installation LED display screens that need to display computer screens synchronously, a video processor can be used in conjunction with a control computer. For outdoor full-color LED display screens on storefronts, to facilitate editing and updating programs and to have enough space for control equipment, an asynchronous playback box can be selected.

It can serve as an independent control platform, with a small size, light weight, can store videos, images, and text on its own, and can be placed inside the LED display screen cabinet for easy movement and maintenance.

b. Choose from the effect display To make the display more delicate and realistic, achieving point-to-point display requires outputting video from the computer to the video processor to the LED display screen without compression or scaling, which is lossless playback, presenting a display effect that is proportional.

This requires using a computer + video processor for matching. For example, if the resolution of the LED display screen is 25601152 and you want to achieve point-to-point display, the resolution of the computer monitor and the requirements of the graphics card should be greater than or equal to 25601152. In this case, you can choose a 4K monitor and match it with a video processor capable of loading a resolution of 2560*1152, which can complete the solution selection.

c. Consider from the perspective of convenience of operation and economy When matching control solutions in some scenes, practicality and economy need to be considered. If a single asynchronous playback box can achieve the required functions, and there is space to place equipment and save budget costs, and the displayed content and presented images are relatively simple, and the resolution of many LED display screens is not very large, if a single asynchronous control box is sufficient, then an asynchronous playback box can be considered.

If a video processor is selected, it needs to be used with a control computer, which will increase the budget. However, if the resolution of the LED display screen is large enough and exceeds the load capacity of the asynchronous playback box, and the hardware, the number of network ports is not enough, then a video processor must be used for matching.

Currently, the maximum number of network ports for asynchronous playback boxes on the market is 6, and the maximum load capacity is 230W. Because the maximum load capacity of a single network cable is 65W Dots, it can only be greater than or equal to 65W Dots.

But if the overall resolution of the LED video wall exceeds 230W, then a video processor must be used to match the control computer solution, or a video processor with a playback box solution, the video processor is responsible for loading the LED display screen, and the playback box is only responsible for storing and outputting video and picture functions, which can save space for placing the control computer.

Can the new version of the control card be compatible with the old version of the control card? If the production time interval of the control card is long, it is not recommended to mix use. LED display control card manufacturers will optimize fault points based on customer feedback and often upgrade the firmware and versions of receiving cards, which will optimize and upgrade debugging software. This may cause the old version of the receiving card to be incompatible with the new version of the software, or unable to find the corresponding old version software. Moreover, this usage method has not been validated for its stability, and there may be many uncertainties in its use.

What is the maximum length of the main network cable used to control LED display screens?

What is the best solution when the transmission distance exceeds the limit? Within 100 meters. By testing with a Fluke network cable signal attenuator for Category 5e and 6 standard network cables, the optimal length of the main network cable from the LED display screen to the video processor is within the range of 100 meters, where the signal is optimal. When it exceeds 100 meters, for every additional 1 meter length, the signal will attenuate by 0.13 dB.

When the transmission distance exceeds 100 meters, fiber optics can be used for conduction. For transmission efficiency, single-mode multi-core fiber optics can be used, with a transmission distance ranging from 1 km to 10 km. For economic suitability and cost-effectiveness, multi-mode fiber optics can be selected.

In the system topology: Control computer – HDMI – Video processor – Network cable – Fiber optic transceiver (transmitter) – Fiber optic cable – Fiber optic transceiver (receiver) – Network cable – LED display screen. This type of system configuration is mainly used in scenarios such as stadium live LED display screens, stadium LED displays, large-scale conferences, and music halls. Moreover, this solution is widely used in LED display screen applications and runs very stably.

Conclusion

This article systematically analyzes the modular design principles of LED control systems and LED screens, and introduces the advantages of the “array” control system in LED screen control technology at the end. It is very helpful for friends who want to deeply understand LED screen control systems.

The AnyDesk software and install it, then send the control code to our engineers. After our engineers connect your computer, they can easily control your computer to debug the LED display.