Customize Your Best Flexible LED Display Shape

JYLED flexible LED display manufacturer can customize it into any shape you want according to your needs, whether it is a beer bottle, Coke can, trapezoid, cylindrical, etc., it can be perfectly presented.

We can quickly produce the above common shapes. If you have other special shapes that need to be customized, you can send us your drawings and we will help you realize it.

Common flexible LED display shapes:

- Cylindrical

- Spherical

- Sector

- Ribbon shape

etc.

All products of flexible LED display

Flexible screen display is an LED screen that can be freely customized. The shape, area and size can be customized according to the actual application.

Ultra-thin flexible LED display is an upgraded product. It uses more advanced technology to compress the thickness of the flexible LED screen to form an ultra-thin flexible LED screen.

Through flexible LED modules, various strange shapes can be produced, such as water drops, Coke cans, beer cans, etc.

On the basis of the flexible LED display, unique outdoor waterproof and high-brightness functions are added, so that it will not be affected by the environment when used outdoors.

JYLED Flexible LED Display Advantages

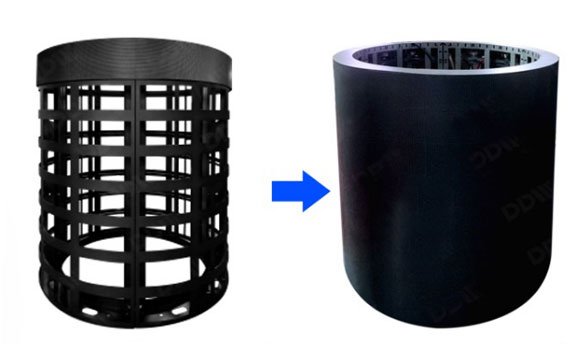

The flexible LED display uses flexible PCB and can be spliced at will.

Shapes such as balls, cylinders, cones, beer bottles, Coke cans, etc. can be customized according to needs.

The flexible LED display adopts a magnetic design, which makes installation quick and convenient.

The magnetic design only needs to be removed from the front when maintenance is needed.

Lightweight Material

The single flexible module measures only 170 grams, making it easy for installers to carry and operate due to its lightweight design.

Easy To Install

The unique magnetic design allows it to be quickly and easily installed at the required location, whether in an indoor or outdoor environment, reducing labor and material resources during the installation process.

Custom Shape

Due to the design of the flexible module, it has excellent flexibility and adaptability. It can be bent to adapt to different surface shapes and angles, providing designers with more design creativity.

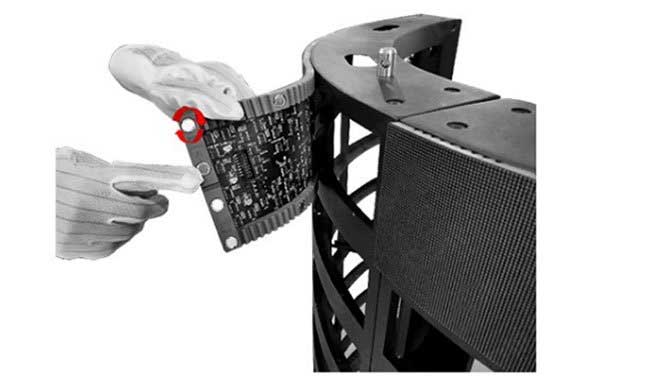

Introduction To Flexible LED Display Installation

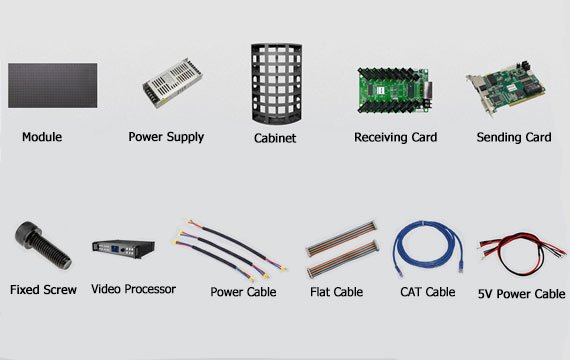

Prepare Material

Flexible LED Module,Signal Cable,Data Cable,Power Cable,Sending Card,Video Processor,Fixed Screw, CAT Cable,Receiving Card,Cabinet

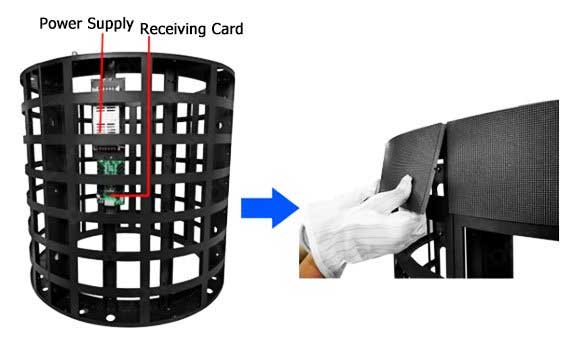

Wear gloves first, gently pick up the flexible LED module to avoid bumping the lamp beads, and then stick it on the customized steel structure to cover the entire cabinet.

After attaching the module, plug in the cables between the modules, then light up the screen to see the entire screen display effect. If there is a problem with the module, just remove it and replace it with a new one.

Flexible LED Display for Different Scene

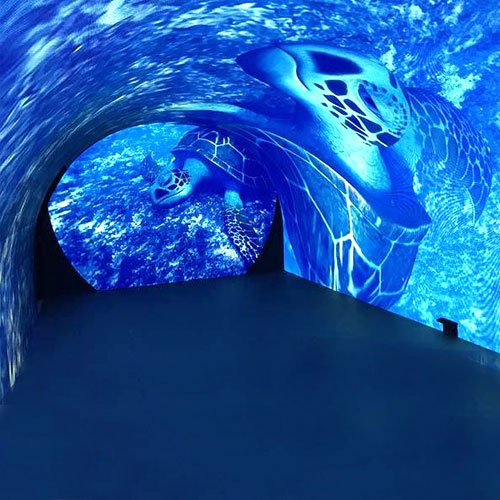

Flexible LED Displays can adapt to the curves or special designs of the aquarium buildings, showing a unique aesthetic. Moreover, playing some carefully designed pictures can be integrated with the wonderful scenery of the seabed, giving the audience an immersive feeling.

On the company’s front desk, flexible LED displays can be used to display exquisite pictures, product promotions or company development history to attract the attention of customers or company employees negotiating cooperation.

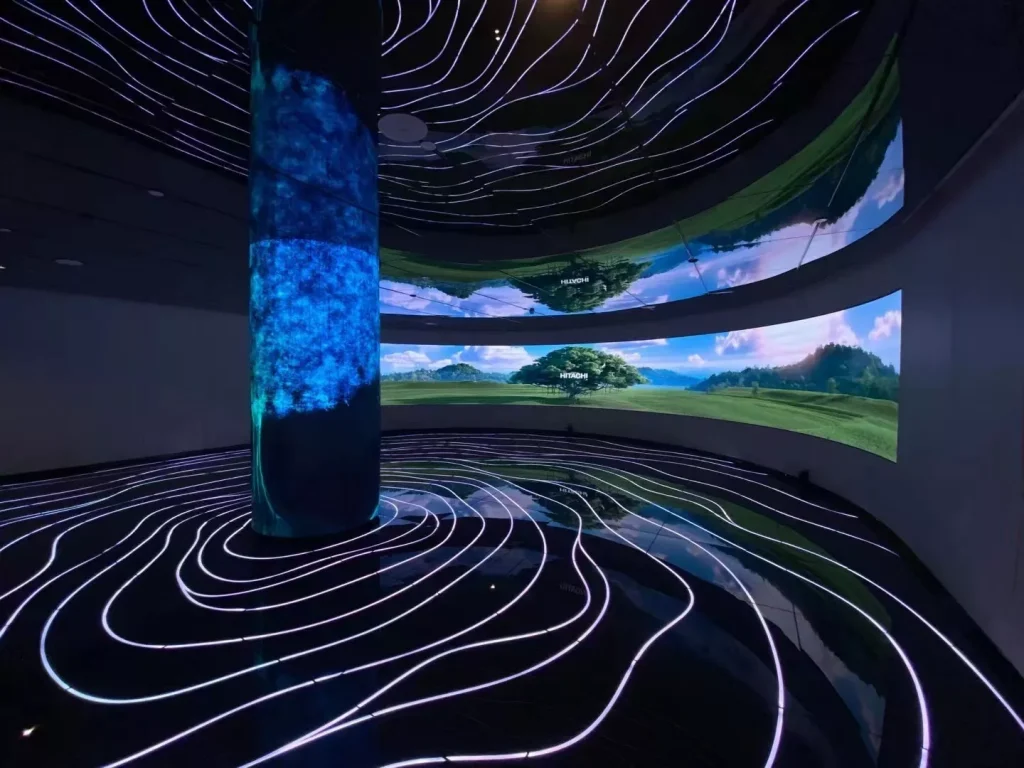

At exhibitions, flexible LED displays can be used to display the company’s brand information in a carousel, making the booth more dynamic and interactive.

This unique shape can also be used to attract exhibiting customers to come for sightseeing, greatly improving the company’s brand promotion.

- Gallery

- Data Sheet

Flexible LED Display Detail Parameter

Flexible LED display parameters table for different models

| Model | P1.875 | P2 | P2.5 | P3 | P4 |

| Pixel Pitch | 1.875 mm | 2 mm | 2.5 mm | 3 mm | 4 mm |

| LED Type | SMD1515 | SMD1515 | SMD2121 | SMD2121 | SMD2121 |

| Configuration | 1R1G1B | 1R1G1B | 1R1G1B | 1R1G1B | 1R1G1B |

| Module Size | 240*120 mm | 240*120 /320*160mm | 240*120 /320*160mm | 240*120 mm | 240*120 /320*160mm |

| Pixel Density | 284444 pixel/㎡ | 250000 pixel/㎡ | 160000 pixel/㎡ | 111111pixel/㎡ | 62500pixel/㎡ |

| Refresh Rate | ≥ 3840Hz | ≥ 3840Hz | ≥ 1920Hz | ≥ 1920Hz | ≥ 1920Hz |

| Gray Scale | 14 Bit | 14 Bit | 14 Bit | 14 Bit | 14 Bit |

| Brightness | ≥ 600 cd/㎡ | ≥ 600 cd/㎡ | ≥ 600 cd/㎡ | ≥ 600 cd/㎡ | ≥ 600 cd/㎡ |

| Scan Way | 1/32 | 1/30 | 1/24 | 1/20 | 1/16 |

| Frame Rate | 50HZ~60HZ | 50HZ~60HZ | 50HZ~60HZ | 50HZ~60HZ | 50HZ~60HZ |

| Viewing Angle | H:140°, V:140° | H:140°, V:140° | H:140°, V:140° | H:140°, V:140° | H:140°, V:140° |

| Max.Current | 3A/Panel | 3A/Panel | 3A/Panel | 3A/Panel | 3A/Panel |

| Avg.Power Consumption | 15W/Panel | 15W/Panel | 15W/Panel | 15W/Panel | 15W/Panel |

| Control System | Nova/Linsn | Nova/Linsn | Nova/Linsn | Nova/Linsn | Nova/Linsn |

| Operation System | Windows XP/7/10 | Windows XP/7/10 | Windows XP/7/10 | Windows XP/7/10 | Windows XP/7/10 |

| Working-Temperature | -20℃~60℃ | -20℃~60℃ | -20℃~60℃ | -20℃~60℃ | -20℃~60℃ |

| Working Humidity | 10%~90% RH | 10%~90% RH | 10%~90% RH | 10%~90% RH | 10%~90% RH |

| Input Voltage | 5V DC input | 5V DC input | 5V DC input | 5V DC input | 5V DC input |

| Data Input | Hub75D (IDC16) | Hub75D(IDC16) | Hub75D(IDC16) | Hub75D(IDC16) | Hub75D(IDC16) |

| MTBF | 35000 Hour | 35000 Hour | 35000 Hour | 35000 Hour | 35000 Hour |

| Lifespan | 100000 Hour | 100000 Hour | 100000 Hour | 100000 Hour | 100000 Hour |

| Certification | CCC,CE,RoHs,ETL | CCC,CE,RoHs,ETL | CCC,CE,RoHs,ETL | CCC,CE,RoHs,ETL | CCC,CE,RoHs,ETL |

Related Product

Flexible LED display introduce

flexible LED display is a dynamic, breathtaking, and cutting-edge curable LED display that creates boundless opportunities for custom shape configurations without sacrificing quality.

Experience true HD-quality video with the creative freedom that allows customers to redefine the space in ways that were not possible before.

We specialize in custom flexible LED screens for broadcast studios, featuring exceptional quality, fully customizable pixel pitches as small as 1mm, high refresh rates, gen lock capable systems, superior black levels, and minimal moire effect—making our products ideal for such a demanding environment.

Flexible panels can be clipped with magnets to a metal structure for a perfect seamless curve and easy maintenance.

Flexible LED display units are ideal for special-shaped LED screens. Flexible LED modules are designed for artistic and creative LED Screen applications.

Made of soft PCB board, it’s soft to fit into any curved surface. To make an artistic design, It’s ideal to be used in museums, galleries, studios, shopping malls, stadiums, hotel lobbies, airports, etc.

Flexible LED displays are made of soft PCB LED modules. Since each flexible LED module can bend to a certain extent, it can form various shapes after splicing and combination.

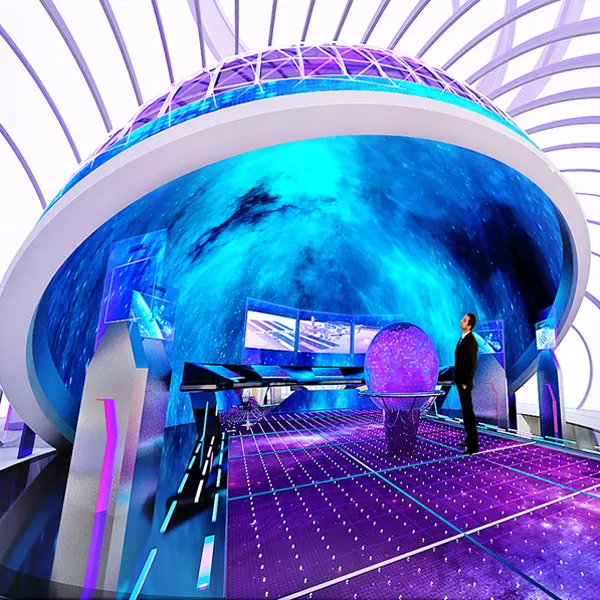

Due to the creative customization of flexible LED displays, they are very suitable for immersive experiences with changing shapes, so we can see the unique effects brought by flexible LED displays in many fantasy experience halls.

Flexible LED displays can create various strange shapes. For images that need to be designed and displayed with more complex shapes, flexible LED displays are the best choice.

The LED flexible display screen is mainly composed of LED soft module unit boards. The reason it has a certain bending amplitude characteristic is mainly related to the raw materials of the PCB circuit board used in the product. Conventional LED display unit boards use ordinary PCB circuit boards, which are generally called rigid circuit boards. The intuitive feeling is that it is a rigid board that cannot be bent, similar to rigid plastic.

The flexible LED display uses a PCB circuit board made of a flexible insulating material. Therefore, it not only has bending characteristics but also has stronger dust and heat resistance than ordinary LED displays. As a result, the price will be slightly higher than that of ordinary LED displays.

The PCB circuit board’s thickness used in conventional LED display screens is generally 1mm, 1.2mm, 1.6mm, 2.0mm, etc. In most cases, the thicker the PCB thickness, the more reliable the stability of the LED screen product, as it is a rigid board. Therefore, under normal circumstances, most of the daily shapes seen are squares, rectangles, diamonds, etc. Spherical and cylindrical display screens cannot be realized, and solutions for arc-shaped design LED display applications are rarely used.

However, with the industry’s development in recent years, ordinary LED displays can no longer meet the industry\’s needs. The emergence of special-shaped screen modules has enabled LED advertising screens to achieve various shapes. For a long time, LED special-shaped screens have been realized by traditional rectangular flat module assembly or wrapping, such as common curved and circular screens.

However, when the arc of the display screen is small and the display form is more complex, the splicing and hemming of special-shaped modules will not solve the seam and flatness, resulting in the inconsistent display, mosaic, and other issues, making the display screen overall The effect is not good, and to solve this problem, a “flexible display” came into being.

However, when the arc of the display screen is small and the display form is more complex, the splicing and hemming of special-shaped modules will not solve the seam and flatness, resulting in the inconsistent display, mosaic, and other issues, making the display screen overall The effect is not good, and to solve this problem, a “flexible display” came into being.

New features of the LED display industry-flexible LED display

It is understood that the many advantages of LED flexible displays are beyond the reach of ordinary curved displays. The connection surface of the LED soft module special-shaped screen is different from that of traditional displays. The traditional PCB board is made of glass fiber material, while the flexible module is equipped with a high-strength, strong magnetic core connection device made of the flexible insulating substrate. FPC circuit boards, masks, and bottom shells are made of high-temperature, bending-resistant silicone materials, with high-strength compression and distortion resistance, which can perfectly solve all kinds of installation difficulties when turning corners and edges.

Most installation methods use magnetic column suction, and the “one-install-ready” installation method is adopted. This means that the shape is customized according to the customer’s needs, and then it can be directly adsorbed to achieve a one-step installation. The magnetic installation method is as simple as the conventional indoor screen installation method, and the cabinet connection lines are all connected by the speed connector, which is firm and reliable.

Today, as products in the industry become increasingly homogenized, most small and medium-sized display companies have to find ways to survive and create unique products. Flexible displays can be shaped arbitrarily because of their good ductility. This is a “weapon” for realizing various creative displays.

In the past few years, there are not a few LED screen manufacturers that have developed flexible display screens, but LED flexible screens have been in a tepid state. However, with the development of creative displays, the development potential of flexible displays should not be underestimated. In particular, with the advancement and prosperity of my country’s cultural undertakings and the prevalence of cultural performance activities, the application demand for LED flexible screens will greatly increase, and the market share will also soar. The prospects for flexible display screens are bright.

In the past few years, there are not a few LED screen manufacturers that have developed flexible display screens, but LED flexible screens have been in a tepid state. However, with the development of creative displays, the development potential of flexible displays should not be underestimated. In particular, with the advancement and prosperity of my country’s cultural undertakings and the prevalence of cultural performance activities, the application demand for LED flexible screens will greatly increase, and the market share will also soar. The prospects for flexible display screens are bright.

Flexible LED displays are usually used in special-shaped display occasions. The entire product includes visual design, structural design, structural construction, and LED display systems. Therefore, when evaluating the price of such products, the cost of the LED display system can be evaluated on the premise of considering the feasibility of the product.

At present, LED flexible display screens are mainly used in science and technology museums, museums, art galleries, and other occasions. Combining the atmosphere of the scene and the special-shaped flexible LED display screens cooperate to create a scientific and technological design. At present, flexible LED display screens still have some technical shortcomings, and it is difficult to deal with the complex outdoor environment. Therefore, the current flexible LED display screens are mainly used indoors and half-indoors.

Without considering the design cost, structure cost, labor cost, frame, and other system accessories. The LED flexible screen can calculate the price from the following aspects

(1) Module spacing

Take P2 and P2.5 as examples to show their prices. Currently, on the market, the price of a P2 flexible LED display is generally 8000-9500RMB/m²; the price of a P2.5 flexible LED display is generally 5000-6500RMB/m², the larger the spacing, the lower the price. The price here is only calculated based on the price of the flexible screen module for the entire screen, excluding the frame, mounting bracket, and other system accessories. And when the market price fluctuates, the overall cost fluctuates greatly.

(2) Module chip brand

Jingtai, National Star, San’an, Jingtai, Xinguangtai, etc. Use different brands, and the price will have a more obvious gap. This is the same as the mobile phones we use in our daily life, which are worth 7000 and 8000, as well as 700 and 800. Module chips of different brands have different workmanship and materials.

(3) Refresh frequency

The refresh frequency is also called the vertical frequency, that is, the vertical scanning frequency of the display. It refers to the number of times the display can display images per second, and the unit is hertz (Hz). The higher the field frequency, the more times the image is refreshed, the smaller the flicker of the image display, and the higher the picture quality.

Note that the so-called “refresh times” here and the “picture frame number (usually expressed in FPS)” that we usually say when describing game speed are two completely different concepts. The latter refers to the scanning frequency of the electron gun of the kinescope displayed by the dynamic image processed by the computer per second.

The lamp beads and chips used by different modules are different, and the refresh rate is also different. The effect displayed by the high refresh rate is better than the effect displayed by the low refresh rate, so the corresponding price of the high refresh rate will be more expensive. Some.

(4) Other expenses

The above three expenses accounted for the most costly, but some other expenses are also not small. For example, the cylindrical screen of a large underground shopping mall was installed by JYLED in Thailand before, from site surveys, and design drawings to construction, and then To the end, it took 5 months before and after. The cost of a worker for a day is as high as 700 RMB a day, which is not a small expense when combined.

The LED flexible screen is a kind of the latest ultra-thin flexible LED screen, including the LED display unit and the signal processing unit, power supply unit and circuit connected to it through the circuit board are all flexible.

With its beautiful embossed lines and various unique shapes, it can give people dynamic beauty under the change of colors.

We often see a lot of cylindrical screens when we go shopping in the mall, as well as some other LED screens of different shapes. The screens are filled with beautiful video content, including the promotion of clothing brands, cosmetics, and Products such as shoes, etc., these video content can easily attract our attention, and let us remember the names of certain brands imperceptibly so that when we buy related products in the mall, we will Unconsciously choose the brand product that I have seen in the LED display. This is why businesses prefer to use LED displays to advertise their products or services and LED cylindrical screens and other LED displays of various shapes are more suitable for decoration in shopping malls, which is also a combination of beautiful designs.

With the development of science and technology, people are no longer satisfied with flat display screens and begin to pursue various artistic styles, and special-shaped screens have also entered the public’s field of vision. As a soft module product for making special-shaped screens, they are even more popular with the public. LED The company has always occupied a larger market in soft module products.

With the development of science and technology, people are no longer satisfied with flat display screens and begin to pursue various artistic styles, and special-shaped screens have also entered the public’s field of vision. As a soft module product for making special-shaped screens, they are even more popular with the public. LED The company has always occupied a larger market in soft module products.

The flexible display screen built for the command center this time has a cylindrical shape, which fits the architectural design of the command center. The cylindrical screen adopts a special design circuit layout PCB multi-layer process design, and the best bending angle is >135°.

Principle of flexible LED display drive circuit

The Design of a Conventional Driving Circuit for an LED Display Screen

The LED display drive circuit is designed to be compatible with the control system and is typically categorized into two modes: dynamic scanning drive and static latch drive. In a dynamic scanning drive, the rows of light-emitting diodes on the display screen share a set of column drive registers and each row\’s lighting time accounts for a fraction of the total time. By leveraging the human eye\’s visual persistence effect, a complete text or image can be seen if the refresh rate is greater than 50 Hz.

The conventional drive circuit uses serial-in and parallel-out general integrated circuit chips for column data latches and low-power NPN transistors for column drives. If a monochrome dot matrix is used, several cascaded integrated circuit chips and line scanning tubes are required. The system sequentially moves and latches data for each row, controlling which LEDs are lit via the corresponding transistor. This process repeats rapidly to form a complete text or image.

The LED display circuit is categorized into two modes: dynamic scanning drive and static latch drive, based on the control system used. In the dynamic scanning drive mode, each row of the light-emitting diodes on the display screen shares a set of column drive registers, and the lighting time of each row is a fraction of the total time. A complete text or image can be seen by using the visual persistence effect of the human eye as long as the refresh rate of each line is greater than 50 Hz.

The conventional drive circuit for a monochrome dot matrix uses serial-in and parallel-out general integrated circuit chips for column data latches and low-power NPN transistors for column drives. The system requires several cascaded integrated circuit chips and line scanning tubes. The data for each row is moved and latched sequentially, controlling which LEDs are lit via the corresponding transistor. This process rapidly repeats to form a complete text or image.

The defects of the conventional drive circuit

Although the design structure of the conventional drive circuit is relatively simple, it has two defects:

(1) When a certain row of row driving tubes is valid, the lighting current of all LEDs corresponding to the row will flow through the row of driving scanning tubes, and the number of LED tubes lit in a row depends on the display. The text or graphics are constantly changing, so the current flowing in the line scanning tube has a large change, which will change the pressure drop of the tube;

(2) The change in current caused by the number of lit L ED tubes will also affect the fluctuation of the power supply voltage value, which will affect the voltage at both ends of the first row of L ED tubes, making it continuous with different display texts or graphics. Fluctuations affect the uniformity of the brightness of the entire display.

Therefore, the author designed a column constant current drive circuit. This method can eliminate the fluctuation of the power supply voltage and the line scan.

The influence of the change of tube pressure drops on the brightness of the LED display screen. Figure 3 shows the relationship between the relative brightness of a light-emitting diode and the current flowing in it. It can be seen from the curve that: within a certain forward current working range, its luminous brightness is approximately proportional to the current flowing in it.

It is a current-driven device. Therefore, as long as the current flowing in each LED light-emitting tube can be guaranteed to be constant, the brightness can be guaranteed to be consistent.

It can be seen from the working principle of the conventional drive circuit that because the row and column drive tubes are all working in a saturated state,

The magnitude of its current cannot be controlled, so the fluctuation of the external power supply voltage, the change of the voltage drop of the horizontal scanning drive tube, etc., directly affects the current flowing in the LED light-emitting tube, that is, it changes its display brightness. If the column drive tube is changed from the saturation state to the linear amplification state and becomes a constant current drive, the unevenness of the display screen brightness caused by the above factors can be eliminated.

The magnitude of its current cannot be controlled, so the fluctuation of the external power supply voltage, the change of the voltage drop of the horizontal scanning drive tube, etc., directly affects the current flowing in the LED light-emitting tube, that is, it changes its display brightness. If the column drive tube is changed from the saturation state to the linear amplification state and becomes a constant current drive, the unevenness of the display screen brightness caused by the above factors can be eliminated.

The column constant current drive circuit is shown in Figure 4.

When the power supply voltage VDD is stable, the high-level output voltage V of 74HC595 is also very stable. For example, when the power supply voltage VDD is 6V, V = 5.9V. So when a certain bit of 74HC595 output is high, the L ED of its corresponding column will be lit, and the current flowing in it is approximate:

As long as the values of R 1, R 2, and R 3 are selected reasonably, the current flowing in the LED can be guaranteed to be stable, and the LED light-emitting diode can work in the best state of forward current and corresponding luminous brightness.

With this column\’s constant current driving mode, it can be achieved that no matter how many LED tubes are lit in a row, although the tube voltage drop of the row driving tube still changes, the power supply voltage VCC can also be changed. The current flowing in the LED light-emitting diode is constant, thus ensuring the uniformity of the brightness of the LED display.

5 Concluding remarks

Compared with the original conventional drive circuit, the LED display constant current drive circuit overcomes the shortcomings of the conventional drive circuit with only minor changes and ensures more perfect performance. The author has passed the actual use of multiple displays All have got the ideal display effect.