Beginning

LEDs are almost an inescapable part of daily life, from outdoor streetlamps to the digital screen outside a shopping mall.

As technology advances, conventional LED models are no longer the go-to choice. GOB LED Display and COB LED display are two of the more recent developments in the field.

This write-up will look into two technologies that are superior to their predecessors and the advantages and disadvantages of each, as well as the uses of each.

Gob LED Display Defined

This article will discuss the definition of Gob LED Display and what it is.

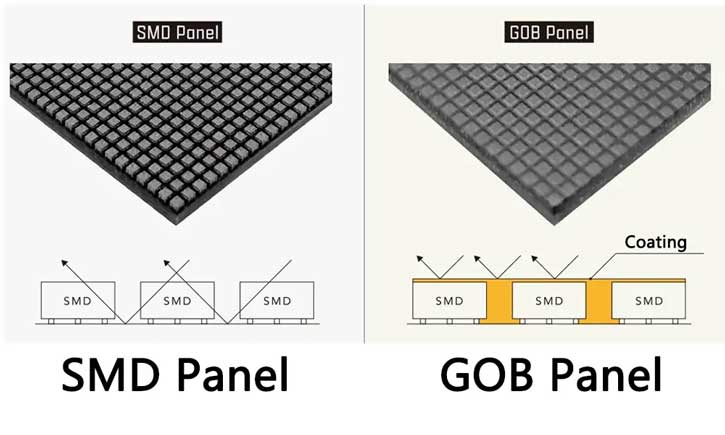

The Gob LED Display utilizes a glue-on board (GOB) technology to create an LED Display. This tech encases the module in protective transparent epoxy glue, making it anti-collision, waterproof, anti-UV, and dustproof. Furthermore, heat dissipation from the shield glue increases the lifespan of these LEDs.

The GOB technology safeguards LEDs from any unexpected mishaps, such as dropping, during installation or delivery, thanks to its shockproof feature.

Not only does this technology ensure ultra-high transparency performance, but it also provides ultra-high thermal conductivity.

When compared to other tech, GOB is much easier to maintain and is more cost-efficient and longer-lasting. It is highly versatile and can be employed in any kind of atmosphere, no matter the weather.

Although GOB has not become widespread yet, its anti-knock feature, which reduces risks, will likely make it more commonplace in the future since it is a requirement for displays that require LED diode protection.

Advantages and Disadvantages of Gob LED Display

The advantages of GOB LED Display are numerous, such as:

Resistant to shocks

LED displays are made shockproof through GOB technology; this substantially reduces the likelihood of damage during either installation or transit.

Reducing Detonation

With the GOB LED display, the glue serves as a protective shield that prevents the display from being cracked because of impact. Consequently, the barrier created by the adhesive helps to avoid damage to the monitor.

Avoidance of Collision

The chances of a crash happening due to something falling during the assembly, delivery, or installation process are greatly lowered when using GOB’s protective adhesive.

Resistant to Dust

GOB LEDs are equipped with glue board technology that shields them from dust. This dust-resistant quality helps to preserve the superior quality of the LED.

Resistive to water

All technology can be threatened by water, however, the GOB LEDs are built to be water-resistant. If they come in contact with rain or any other liquid, the glue on the board design will act as a shield, preventing the water from entering the LED and thus providing protection.

Trustworthy

GOB LEDs are exceptionally dependable. As they have been created to be resistant to most risks such as damage, humidity or any impact, they can be used for a long time.

Adverse effects

The downsides of utilizing GOB LED Display could include

Challenges in fixing

A downside of GOB technology is the difficulty of repairing LEDs that are secured with glue. While this helps to protect them from knocks and collisions, it also makes them harder to fix.

Shaping of PCB boards

With the use of a high-pressure adhesive, the PCB boards are affixed to the screen, consequently resulting in a possible distortion of the flatness of the display.

Modification due to Heat

The risk of discoloration of colloids and partial drumming increases when exposed to temperature fluctuations between hot and cold.

Image of a lesser degree

The colloid creates a secondary optical image, hindering the observer’s ability to view the effects on the luminous surface of the LED Display.

Misidentification of welding

Another way of saying it could be: Repairing GOB LED Displays can be a challenge when they have been welded incorrectly.

Uses of GOB LED screen technology

GOB LED technology offers plenty of potential uses and applications. This type of display technology is suitable for both indoor and outdoor settings, making it a highly versatile choice. It is often used for advertising, product promotion, and displaying dynamic content.

More recently, GOB LED displays have been used in the medical and industrial sectors for providing real-time and detailed information. As the technology continues to evolve, it is likely to be employed in a variety of other sectors as well.

Particular LED screens are more likely to be harmed than the rest. GOB technology is a must-have for these screens, as it not only defends them from damage but also helps you save a lot of money.

LED displays requiring GOB technology include:

Hiring out LED screen

LEDs that are rented out are subject to a lot of movement and handling, including assembly, installation, breakdown, packing and transport. This can often result in the LED equipment being damaged during one of these steps, which increases maintenance costs due to repair work. GOB technology however can provide a safeguard, ensuring that rental LEDs are secure and protected.

A LED Screen with a Clear View

Due to their slim PCB, transparent LEDs may be vulnerable to harm. Although they are gaining in popularity, any harm done to them can detrimentally affect the resolution and clarity of the display. With glue-on board (GOB) technology, the LED display is kept secure, and safe from any possible impact or damage.

An LED display with a limited area

The pixel pitch of a small-pitch LED display is less than 2.5 mm, which leads to a high risk of being damaged with even a slight force applied to it.

Furthermore, maintenance is costly and challenging. GOB technology offers a solution to this, as it safeguards the screen against any potential damage.

LED Display With Flexibility

By employing GOB technology, the dependability of Flexible LEDs can be reinforced, shielding them from humidity harm, and abrasions, thanks to the usage of soft modules.

LED Screen for Floors

Typically, Floor LEDs have an acrylic layer to safeguard the display. This can compromise the aesthetics and luminosity.

However, GOB technology can prevent this problem. Not only can GOB provide better luminosity and visual effects, but is also equipped with waterproof, shockproof and dustproof features so even if it is stepped on, it is still guarded.

LEDs with Unconventional Shapes

At places such as clubs and halls, LED spherical screens are often used for indoor purposes. Unfortunately, spills and accidental pressure put on the LED display can be unavoidable.

However, GOB technology can protect it from any harm that could be caused by these two factors. Not only this but it can also significantly lower the cost of maintenance.